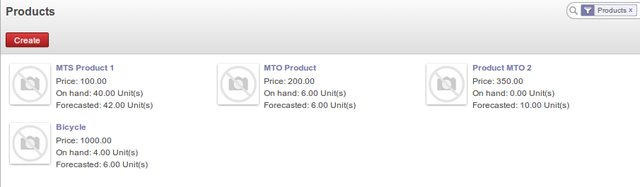

The On Hand Inventory (or quantity on hand) is the quantity physically present in your warehouse.

The Forecasted Inventory (or future or virtual stock) is the actual quantity available, which is calculated according to the following formula: on hand inventory - outgoing + incoming. Virtual or forecasted stock is very useful because it shows what the salespeople can sell. If the forecasted stock is higher than the real stock, this means products will be coming in. If forecasted stock is smaller than on hand stock, certain products are reserved for other sales orders or work orders.

Why these two concepts?

It is clear that your forecasted inventory will decrease with each sale, but what about the on hand inventory? If you have 10 products in your stock location and you sell one, your forecasted inventory will be 9, because there's one product less to sell. However, the product is still physically present in your stock. The On Hand Inventory will remain at 10 until the product leaves your warehouse. Depending on how many products still need to be shipped, your on hand inventory will usually be higher than your available inventory.

Of course, at some point in time on hand and forecasted quantity will synchronise when you receive and deliver all the orders that have been placed. But yet it is most likely that you want to offer more of a product then you have available, for instance in case of backorders or drop shipping, or that you might not want to sell the full quantity of a product, for instance if you want to use some of the products as samples. Whether you want to sell more than you have, or save some of what you have, these two concepts of On Hand and Forecasted Inventory can be very useful.

The Forecasted quantity is also used for Reordering Rules, meaning that such a rule takes into account the calculation of deliveries and receipts to come. To have Odoo generate stock replenishment proposals according to minimum / maximum stock for you, go to the menu Warehouse ‣ Configuration ‣ Reordering Rules (make sure Procurement is installed).

If the forecasted stock for the given location is lower than the minimum stock indicated in the rule, the system will automatically propose a procurement to increase the level of forecasted stock to the maximum level given in the rule.

In a reordering rule, when you indicate a warehouse, it suggests a stock location by default in that warehouse. You can change that default location when the scheduler completes.

No comments:

Post a Comment